Stainless Steel Sub Arc Weld Wires: A Comprehensive Overview

In India, there is a gradual rise in manufacturing activities. This rise has made Stainless Steel Sub Arc weld wires a key player in the welding world. In this article, we will explore what Stainless Steel Sub Arc Weld Wires are, their importance, and their noteworthy manufacturer, Ambica Steels India Limited.

What is Stainless steel sub-arc weld wire?

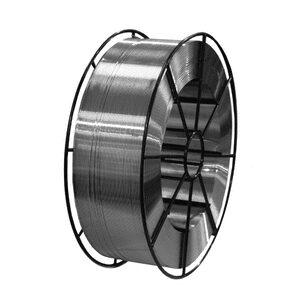

Stainless steel sub-arc weld wire or SS Sub Arc Weld Wire are used in SAW (Submerged Arc Welding). This technique involves fusing the welding wire and the workpiece under a flux layer, which shields the weld. The SS Sub Arc Weld Wire is the consumable electrode which is involved in the welding pool formation.

Stainless Steel Sub-Arc Weld Wire in India

With the rapid growth of manufacturing industries in India, there is also an increase in the need for quality welded products. The stainless steel sub-arc weld wires are extensively used in construction, shipbuilding, as well as the manufacturing industry. These wires are preferred for their resistance to corrosion, strength, and capability to handle high temperatures.

Ambica Steels India Limited – Sub Arc Weld Wire Manufacturers in India

In India, Ambica Steels India Limited is one of the prominent Sub Arc Weld Wire manufacturers. They are one of the leading names in manufacturing welding components. They keep quality and innovation at the forefront of their operations. Ambica Steels has gained prominence as a provider of Sub Arc Weld Wires that are committed to meeting industry standards and ensuring customer satisfaction.

Ambica Steels follows a manufacturing process that involves precision and quality control. They manufacture Sub Arc weld wires that are of the highest quality, ensuring that welders have a reliable and effective tool to use in their welding needs.

Benefits of Stainless Steel Sub Arc Weld Wire

However, Stainless Steel Sub Arc Weld Wire has numerous benefits, making it a common choice amongst welders and industries.

- Corrosion Resistance: Stainless steel is inherently corrosion-resistant. It is a vital aspect, especially in situations where the material is exposed to harsh environmental conditions. SS Sub Arc Weld Wire are, hence, a perfect element for various manufacturing applications.

- Durability: Stainless steel is a durable element that ensures that SS Sub Arc Weld Wire offer durable welded joints. It becomes quite critical in structures and equipment where the integrity of welding is pivotal to safety and functionality.

- High-Temperature Resistance: Stainless steel can stand very high temperatures without losing the structural integrity. It renders SS Sub Arc Weld Wire suitable for applications that require minimal or no exposure to high temperatures.

- Versatility: Stainless steel sub-arc weld wire is very flexible, and it can be applied to many jobs in various industries. It is a vital tool for adaptable welders that have different welding problems.

- Low Maintenance: Stainless Steel Sub Arc Weld wire welded joints require very little maintenance. Therefore, this is suitable for industries that aim to minimize downtime and maintenance costs.

In conclusion, Stainless Steel Sub Arc weld wires have a very important role to play in India, especially in the welding industry. Ambica Steels India Limited is committed to manufacturing Sub Arc weld wires of high quality. They improve the reliability of the vital welding materials. The use of Stainless Steel Sub Arc Weld Wires is anticipated to gain prominence in the welding process as industries progress, thereby increasing the demand for such dependable and long-lasting welding solutions.